Get In Touch Today 0421 209 254

LJ's Technical Services

Non Destructive Testing in Australia

- Reports within 24 hours guaranteed

- Specialising in advanced inspections to ensure the safety and reliability of your assets

- Delivering quality-assured testing and reporting for industries across Australia

- Supporting oil & gas, mining, construction, and more with compliance and safety solutions

Request a Call Back

Thank you for contacting LJ's Technical Services.

We will get back to you as soon as possible.

Please try again later.

LJ's Technical Services

Trusted Nationwide NDT Services

LJ’s Technical Services is Australian-owned and operated, providing non destructive testing (NDT), asset inspections, pressure vessel and production services to the defence, mining, oil, gas, and manufacturing industries.

Our Townsville team works exclusively to maximise the lifetime of our clients’ assets through NACE coating and corrosion surveys, AICIP and API pressure vessels and storage tank inspections, NDT and witnessing services.

Whether on mine sites, fabrication, plant, construction, or maintenance, our asset integrity services provide quality assurance and process safety, reducing downtime and boosting the efficiency and reliability of assets while identifying potentially hazardous risks. We then work closely with our clients to come up with solutions.

All services are supported by an outstanding business management system with all work conducted under NATA and ISO quality. LJ's offers certified multi-skilled technicians for new fabrication or maintenance services, rapid reports (within 24 hours of job completion), competitive rates and local, national and international services.

Discover LJ’s nationwide services in a location near you, including Townsville,

Mackay,

Mount Isa,

Cairns,

Gladstone,

Brisbane,

the Hunter Valley,

the Northern Territory and

South Australia. Call us on

0421 209 254 to discuss your testing and inspection needs.

Non-destructive testing

identifies defects in materials and components without causing damage. This cost-effective method ensures safety, reliability, and compliance while minimising downtime and operational risks across industries.

ISO testing

ensures compliance with international quality and safety standards. It supports businesses in enhancing operational efficiency, improving product reliability, and meeting critical regulatory requirements across industries.

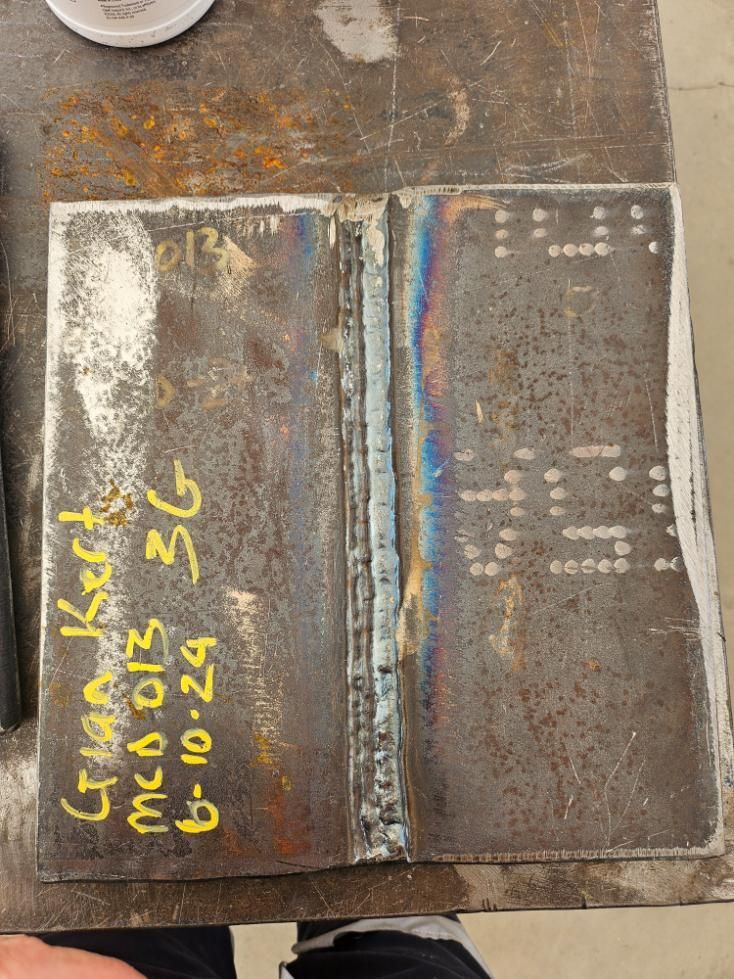

Welding inspection and testing

evaluates the safety and quality of welded joints. This service ensures compliance with industry standards, preventing failures and verifying the structural integrity of critical components.

Ultrasound weld inspections

use advanced sound wave technology to detect internal defects in welds. This precise, non-invasive method ensures safety, quality, and performance in welded structures and components.

Phased array

testing uses multi-angle ultrasonic technology for detailed weld inspections. This efficient method provides fast, accurate results, ideal for complex materials and high-risk environments.

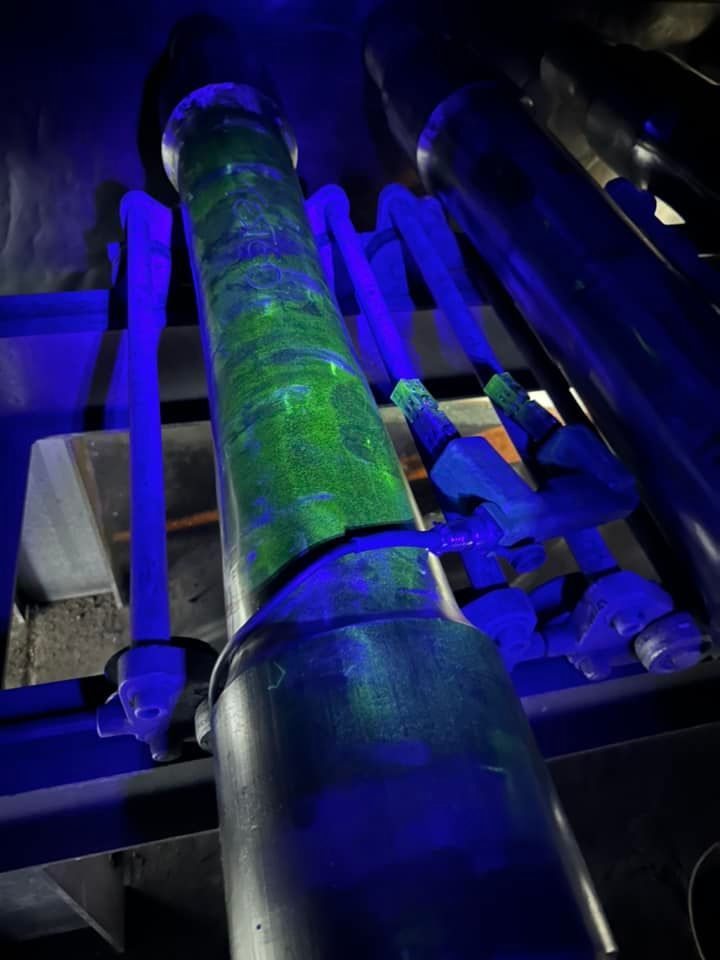

Magnetic particle inspection and testing

detects surface and near-surface defects in ferromagnetic materials. This quick and efficient method ensures reliability and safety in critical metal components.

Dye penetrant inspection and testing

highlights surface-breaking defects by applying a visible or fluorescent dye. This straightforward technique enhances safety and quality across various materials.

Radiography inspection and testing

uses X-rays or gamma rays to reveal hidden material defects. This advanced method ensures the safety and integrity of pipelines, welded joints, and critical components.

Eddy current inspection and testing

uses electromagnetic technology to detect surface and sub-surface defects in conductive materials. It ensures safety and reliability in industries like aerospace and automotive.

Visual inspection and testing

provides a direct assessment of materials to identify visible defects or irregularities. This simple yet effective method ensures compliance and safety in routine inspections.

Ultrasonic thickness and corrosion testing measures material thickness and detects corrosion. This vital service maintains asset safety and extends the life of key components.

Coating inspections

verify the integrity and application of protective coatings. This service ensures compliance with standards, preventing corrosion and extending equipment lifespan.

Hydrostatic pressure testing evaluates the strength and integrity of pressure vessels, pipelines, and tanks by pressurising them with water. This method ensures operational safety and compliance.

Pressure vessel inspections verify the integrity and functionality of pressure vessels, including safety valves. These inspections are critical for maintaining safe and reliable operations.

API tank inspections

ensure storage tanks meet API standards and include vac box testing to assess vacuum integrity. This service prevents leaks and ensures operational safety.

Baroscopic inspections

examine hard-to-reach internal areas using borescopes. This non-invasive method is ideal for turbines, pipes, and confined spaces without requiring disassembly.

Welding procedure and qualifications

verify that welding processes meet regulatory standards. Professional witnessing ensures compliance, safety, and quality control across applications.

Who We Are

Comprehensive Testing & Inspection Services

At LJ’s Technical Services, we understand the importance of maintaining asset integrity. Our wide range of services includes ultrasonic thickness testing, radiography inspections, and coating assessments. These are crucial for identifying potential risks, improving safety, and ensuring compliance with industry standards.

With experience across sectors like energy, aerospace, and marine industries, we tailor solutions to meet unique project requirements. Our team utilises advanced technology to detect defects and prevent costly failures, helping you maintain operational efficiency.

We proudly serve businesses Australia-wide, offering competitive rates and fast turnaround times. Discover how our professional testing and inspection services can support your business. Call us on

0421 209 254 to learn more or book a consultation.

Contact Us

Thank you for contacting LJ's Technical Services.

We will get back to you as soon as possible.

Please try again later.

Locations We Service

Site Link

Location We Service

Our Services

Trading Hours

- Monday

- -

- Tuesday

- -

- Wednesday

- -

- Thursday

- -

- Friday

- -

- Saturday

- Closed

- Sunday

- Closed

ABN: 59 383 740 738

ACN: 149 374 676

Accreditation No. 19154

Date of Accreditation 17 June 2013

ISO/IEC 17025 (2017)