Get In Touch Today 0421 209 254

NACE Coating Inspections – Ensuring Long-Term Protection and Compliance

High-Quality Inspections for Corrosion Prevention & Asset Longevity

NACE (National Association of Corrosion Engineers) Coating Inspections are essential for ensuring that protective coatings applied to metal surfaces are properly applied and remain effective over time. These inspections play a critical role in preventing corrosion and material degradation in assets exposed to harsh environments, such as mining equipment, pipelines, storage tanks, and offshore structures.

What Is a NACE Coating Inspection?

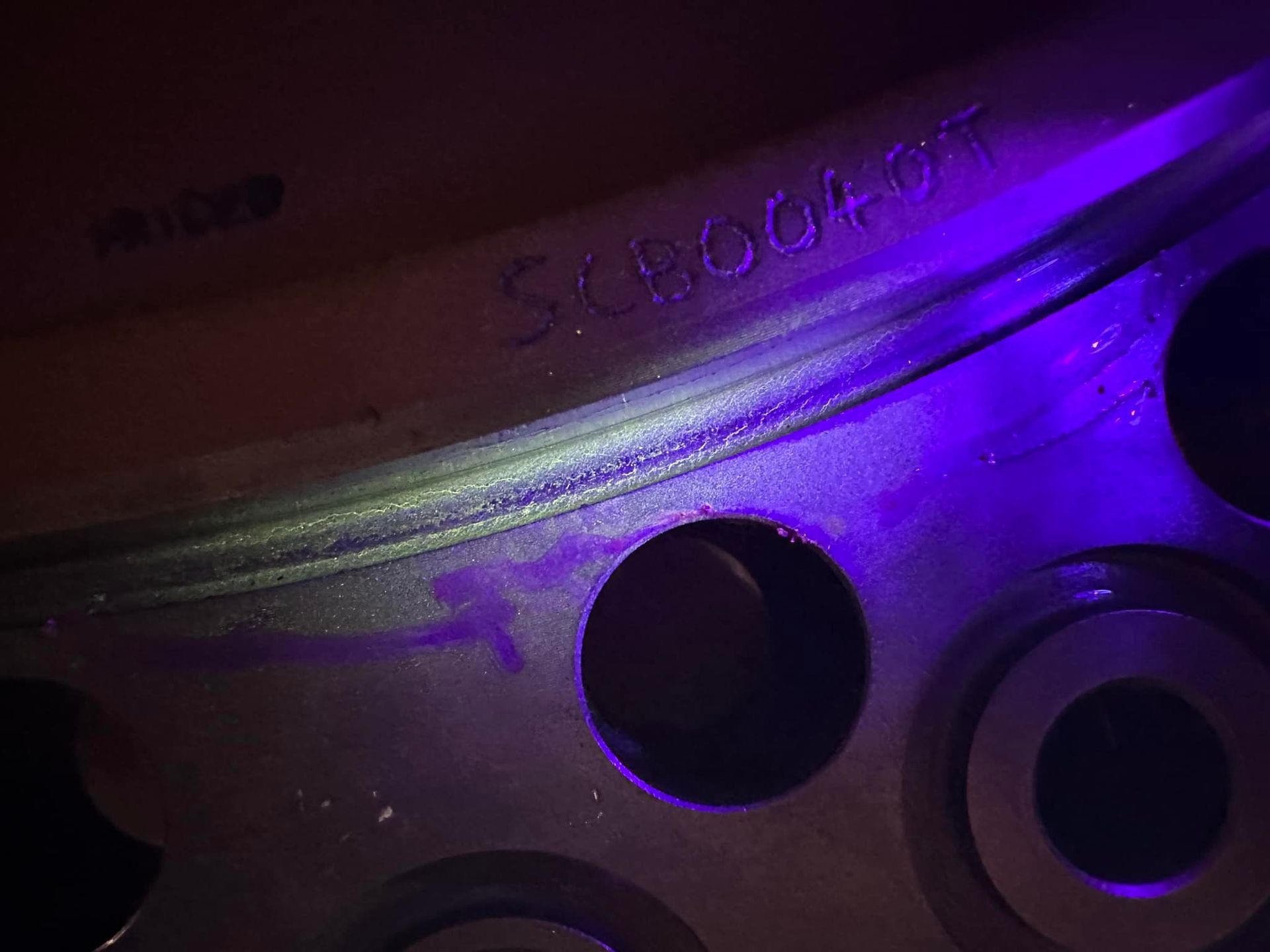

A NACE Coating Inspection involves evaluating the condition and effectiveness of coatings that protect metals from corrosive environments. Our certified NACE inspectors assess whether the coating has been applied correctly and if it is performing as intended to provide the necessary level of corrosion resistance.

- Surface Preparation: Ensuring proper preparation and cleaning of the surface before coating application.

- Coating Thickness Measurement: Using techniques like ultrasonic or magnetic gauges to measure coating thickness to ensure it meets specifications.

- Coating Adhesion Testing: Verifying the adhesion strength of coatings to ensure they will not fail prematurely.

- Visual Inspection: Identifying visible defects such as bubbles, cracks, and poor coverage that could compromise protection.

Why Are NACE Coating Inspections Important?

- Corrosion Prevention: Properly applied coatings are the first line of defense against environmental factors such as moisture, chemicals, and extreme temperatures.

- Extended Asset Lifespan: High-quality coatings reduce maintenance needs and extend the operational life of critical infrastructure and equipment.

- Regulatory Compliance: Ensures that your coatings comply with industry standards and regulations, reducing the risk of non-compliance.

- Cost Savings: Early detection of coating defects prevents corrosion-related damage, which can lead to costly repairs or replacements.

Applications of NACE Coating Inspections

NACE Coating Inspections are critical in industries where assets are exposed to harsh or corrosive conditions. Common applications include:

- Oil & Gas Industry: Ensuring pipelines, tanks, and offshore structures are protected from corrosion.

- Mining Industry: Protecting mining equipment and machinery from wear and corrosion in aggressive environments.

- Marine & Offshore Structures: Coating inspections on ships, rigs, and platforms exposed to saltwater and high humidity.

- Infrastructure & Utilities: Inspecting coatings on

bridges, tanks, pipelines, and

other critical infrastructure.

Why Choose Us?

- Certified NACE Inspectors: Our team of NACE-certified coating inspectors delivers accurate and reliable assessments.

- Comprehensive Testing & Reporting: We provide detailed reports on coating thickness, adhesion, and overall condition.

- Tailored Inspection Services: We offer flexible, on-site services to meet your specific asset requirements and operational schedules.

Ensure Optimal Protection with Professional NACE Coating Inspections

Regular coating inspections are crucial for protecting your assets and ensuring they remain resistant to corrosion.

Contact us today to schedule a NACE Coating Inspection and keep your critical infrastructure performing at its best.

Locations We Service

Site Link

Location We Service

Our Services

Trading Hours

- Monday

- -

- Tuesday

- -

- Wednesday

- -

- Thursday

- -

- Friday

- -

- Saturday

- Closed

- Sunday

- Closed

ABN: 59 383 740 738

ACN: 149 374 676

Accreditation No. 19154

Date of Accreditation 17 June 2013

ISO/IEC 17025 (2017)