Get In Touch Today 0421 209 254

NDT in the Hunter Valley

Specialised solutions for Hunter Valley’s mining and manufacturing sectors, with welding certifications and mapping.

Contact LJ's Technical Services in Hunter Valley

Thank you for contacting LJ's Technical Services.

We will get back to you as soon as possible.

Please try again later.

Supporting Industrial Needs

Industries in the Hunter Valley rely on precise and efficient testing and inspection services to maintain safety, compliance, and performance. Supporting sectors like mining, energy, agriculture, and manufacturing, LJ's Technical Services can help ensure the integrity of assets and the smooth operation of critical systems. Our non-destructive testing (NDT) services are designed to meet the unique challenges of Hunter Valley businesses.

Our expertise includes

visual inspections for quick and effective assessments,

eddy current testing to detect surface and subsurface defects, and

baroscopic inspections offer internal evaluations of hard-to-reach equipment. Our

welding procedure and qualification services ensure compliance with industry regulations and verify the safety and durability of critical systems.

By delivering reliable and customised testing and inspection solutions, we help Hunter Valley businesses reduce downtime, optimise performance, and maintain asset integrity.

Contact LJ’s today on 0421 209 254 to discuss how we can support your operations in the Hunter Valley.

Non-destructive testing

in the Hunter Valley ensures critical components are inspected for flaws without damaging assets or materials.

ISO testing

supports local businesses in the Hunter Valley by achieving compliance with global safety and quality standards.

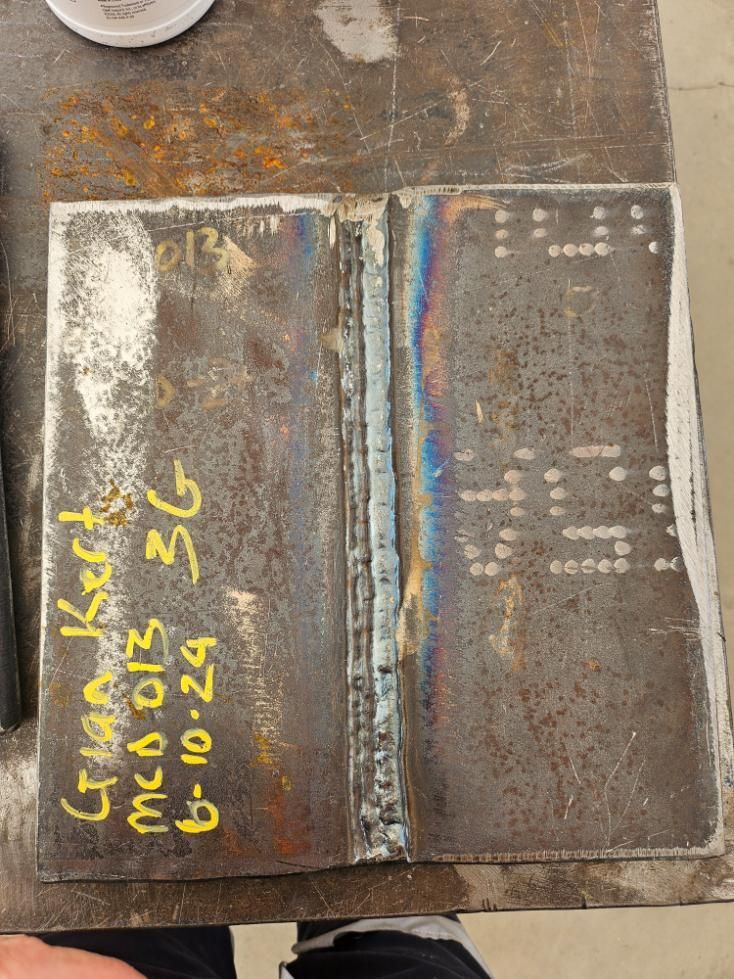

Welding inspection and testing

in the Hunter Valley verifies the strength and safety of welded structures used in industry.

Ultrasound weld inspections

identify internal weld defects, crucial for maintaining equipment reliability in the Hunter Valley.

Phased array

testing in the Hunter Valley offers precise imaging to evaluate weld quality and detect potential weaknesses.

Magnetic particle testing

finds surface defects in ferromagnetic materials, ensuring safety in the Hunter Valley.

Dye penetrant inspection and testing

in the Hunter Valley highlights surface cracks and flaws, vital for maintaining material integrity.

Radiography inspection and testing

provides internal imaging of to ensure safety in high-pressure operations in the Hunter Valley.

Eddy current inspection and testing

in the Hunter Valley detects flaws in conductive materials, supporting infrastructure and heavy industry.

Visual inspection and testing

finds visible defects in the Hunter Valley, ensuring compliance with operational standards.

Ultrasonic corrosion testing in the Hunter Valley monitors material wear and corrosion, extending asset life.

Coating inspection

ensures protective coatings are effective, reducing corrosion in industrial environments in the Hunter Valley.

Hydrostatic pressure testing in the Hunter Valley assesses the strength of pipelines and vessels, ensuring operational safety.

Pressure vessel inspections verify the compliance and safety of high-pressure industrial systems in the Hunter Valley.

API tank inspections

in the Hunter Valley evaluate storage tanks for structural integrity and adherence to safety standards.

Baroscopic inspection

offers internal visual assessments of complex systems to minimise downtime in the Hunter Valley.

Welding procedure and qualifications

in the Hunter Valley ensures welding meets required standards for safety and reliability.

Why Partner With LJ's?

- Mining Industry Expertise: Decades of experience supporting Hunter Valley’s mining and resource sectors with tailored solutions.

- Comprehensive Testing Services: From welding certifications to corrosion monitoring, we provide a full range of inspection services.

- Regulatory Compliance: NATA-accredited services ensure businesses meet all safety and operational standards in Hunter Valley.

- Proactive Asset Maintenance: Regular inspections prevent costly repairs and optimise the performance of critical equipment.

- Detailed Reporting: Clear, actionable insights help businesses make informed decisions about asset maintenance and safety.

- Efficient Service Delivery: Minimised downtime with rapid and reliable testing and reporting processes.

- Cutting-Edge Technology: Utilising the latest tools to ensure precise and dependable results for Hunter Valley projects.

LJ’s Technical Services is your trusted partner in Hunter Valley, providing advanced testing and inspection services to safeguard operations and ensure compliance.

Contact LJ's Technical Services in Hunter Valley

Thank you for contacting LJ's Technical Services.

We will get back to you as soon as possible.

Please try again later.

Frequently Asked Questions

-

What areas do you service in the Hunter Valley?

We proudly provide services across the Hunter Valley region, including Newcastle, Maitland, Singleton, Muswellbrook, Cessnock, and Scone. If your location is not listed here, please contact us to confirm our availability. We are committed to supporting businesses throughout the Hunter Valley and nearby regions with high-quality solutions.

-

Why are coating inspections important?

Coating inspection is crucial for ensuring protective layers on equipment and infrastructure are effective against environmental damage. Industries like mining and manufacturing face exposure to harsh conditions, making corrosion prevention a top priority. Coating inspection assesses the quality and thickness of protective layers, ensuring long-term durability and compliance with standards.

-

What is phased array testing, and how is it used?

Phased array testing is an advanced non-destructive technique that uses multiple ultrasonic beams to assess material integrity. It provides detailed imaging to detect flaws in welds, pipes, and structures. This method is essential for industries like mining and construction, where high-quality inspections are critical to operational safety. Phased array testing helps businesses identify potential weaknesses early, ensuring compliance with safety standards and preventing costly failures.

Phone

Location

Trading Hours

Business Hours

- Monday

- -

- Tuesday

- -

- Wednesday

- -

- Thursday

- -

- Friday

- -

- Saturday

- Closed

- Sunday

- Closed

Other Locations We Service

Site Link

Location We Service

Our Services

Trading Hours

- Monday

- -

- Tuesday

- -

- Wednesday

- -

- Thursday

- -

- Friday

- -

- Saturday

- Closed

- Sunday

- Closed

ABN: 59 383 740 738

ACN: 149 374 676

Accreditation No. 19154

Date of Accreditation 17 June 2013

ISO/IEC 17025 (2017)