Get In Touch Today 0421 209 254

NDT Services in Townsville

Ensure asset reliability with non-invasive testing techniques that detect defects without compromising material integrity.

Non-destructive testing

helps maintain operational efficiency and extend asset lifespans.

Achieve global compliance with

ISO testing, designed to validate quality and safety standards across processes, products, and services. Enhance your business’s reputation with proven testing solutions.

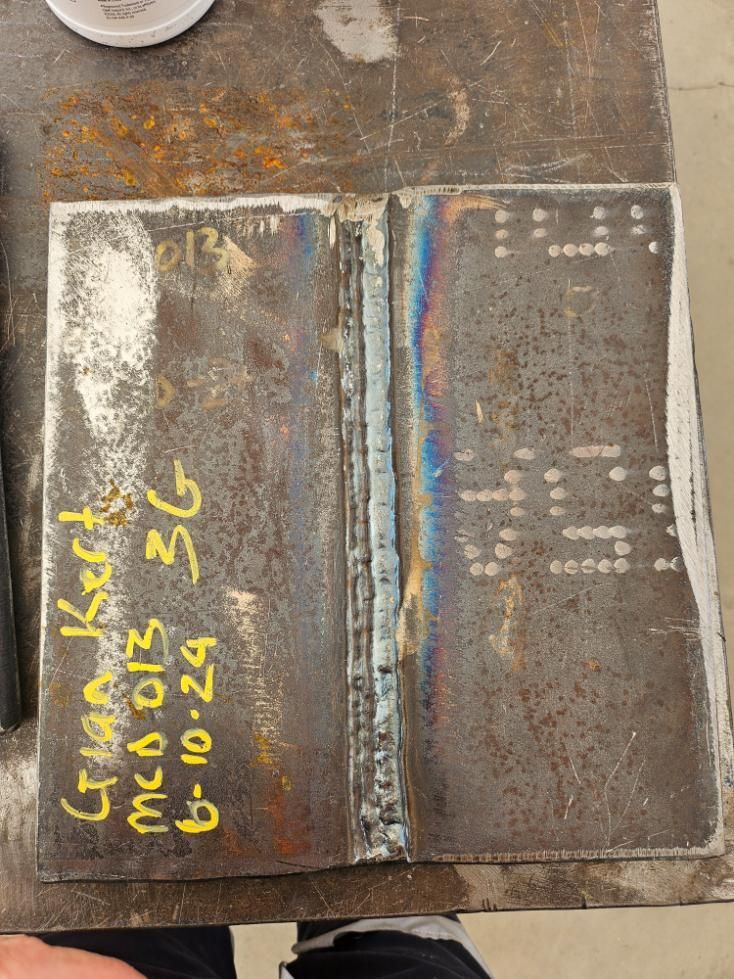

Welding inspection and testing provides assurance that welds meet required safety and quality standards. This service identifies potential risks and ensures the strength of critical connections.

Detect internal weld irregularities with ultrasound weld inspections. Using sound waves, this precise method supports quality assurance in high-stakes environments like pipelines and infrastructure.

Phased array

technology offers advanced, multi-angle inspections of complex materials. This fast, detailed method ensures safety and compliance in high-pressure applications.

Identify cracks and defects on ferromagnetic materials with

magnetic particle inspection. This method quickly highlights issues to maintain performance in components.

Dye penetrant inspection detects surface flaws with ease. Suitable for a variety of materials, this testing ensures visible identification of potential defects in products and structures.

Inspect internal material structures with

radiography testing. By using X-rays or gamma rays, this service uncovers hidden faults to maintain asset integrity.

Eddy current inspection and testing

is a fast, non-contact method for detecting material defects. This technique ensures precise evaluations of conductive materials, critical for safety-focused industries.

A cost-effective way to identify surface irregularities,

visual inspections provide quick results to ensure compliance and resolve visible material concerns efficiently.

Monitor material conditions with

ultrasonic thickness and corrosion testing. This service ensures early detection of thinning or corrosion, preserving functionality and safety.

Safeguard your infrastructure with coating inspections. Verifying the quality of protective layers, this service prevents corrosion and enhances the durability of equipment.

Confirm the strength and safety of pressure systems with

hydrostatic testing. This method verifies equipment reliability by applying water pressure under controlled conditions.

Ensure regulatory standards with

pressure vessels inspections. These checks focus on structural integrity and the performance of pressure safety valves.

Maintain compliance with

API tank inspections. This service includes vac box assessments to verify vacuum integrity, ensuring safe operations for critical storage systems.

Inspect internal components without disassembly using

baroscopic inspection. This method is perfect for hard-to-reach areas like turbine interiors or confined pipes.

Verify

welding standards with certified qualifications and professional witnessing. This service ensures adherence to industry regulations and enhances overall project safety.

Reliable Testing for Asset Integrity

At LJ’s Technical Services, we specialise in providing a wide range of testing and inspection solutions designed to support industries nationwide. From advanced non-destructive testing (NDT) methods to ensure the integrity of materials, to ISO compliance testing and asset management, we deliver services tailored to businesses' unique needs in sectors such as oil and gas, mining, construction, and manufacturing.

Our expertise extends to welding inspection and testing, phased array ultrasonic testing, and radiography inspection, all designed to maintain operational safety and compliance with industry standards. We also provide hydrostatic pressure testing, API tank inspections, and ultrasonic thickness testing to detect material weaknesses and corrosion early.

Contact us today to learn how our NDT services can support your business’s operational goals anywhere in Australia, including Townsville, Mackay, Mount Isa, Cairns, Gladstone, Brisbane, the Hunter Valley, the Northern Territory, and South Australia. Call 0421 209 254 to get started.

Site Link

Location We Service

Our Services

Trading Hours

- Monday

- -

- Tuesday

- -

- Wednesday

- -

- Thursday

- -

- Friday

- -

- Saturday

- Closed

- Sunday

- Closed

ABN: 59 383 740 738

ACN: 149 374 676

Accreditation No. 19154

Date of Accreditation 17 June 2013

ISO/IEC 17025 (2017)