Get In Touch Today 0421 209 254

NDT in Brisbane

Supporting Brisbane’s construction projects with eddy current testing and structural integrity assessments.

Contact LJ's Technical Services in Brisbane

Thank you for contacting LJ's Technical Services.

We will get back to you as soon as possible.

Please try again later.

Industry Testing & Inspection Specialists

As a thriving hub of industry and innovation, Brisbane demands reliable testing and inspection services to support its diverse sectors. From construction and energy to manufacturing and infrastructure, these services are vital for maintaining safety, compliance, and operational efficiency. Using advanced technology and industry expertise, LJ's Technical Services delivers non-destructive testing (NDT) solutions.

We also offer phased array testing for detailed assessments of complex structures and radiography inspections to detect hidden internal defects. Coating inspections protect assets from Brisbane’s environmental conditions, while hydrostatic pressure testing ensures that pipelines and pressure systems meet stringent safety standards.

With a focus on quality and efficiency, we provide trusted support to Brisbane’s industries, helping businesses achieve long-term reliability and safety.

Contact LJ’s Technical Services today on 0421 209 254 to learn more about our tailored testing and inspection solutions for Brisbane.

Non-destructive testing identifies flaws in materials and components without causing damage, ensuring asset reliability in Brisbane.

ISO testing

ensures Brisbane businesses meet international safety and quality standards, critical for diverse industries.

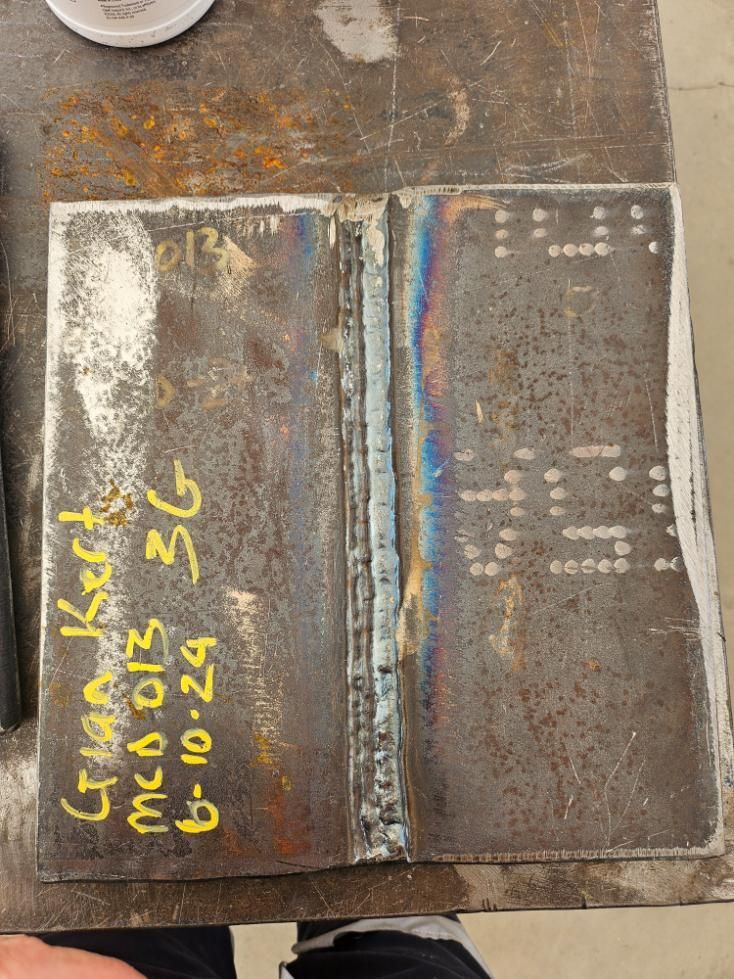

Welding inspection and testing

in Brisbane evaluate weld quality to ensure structural integrity in demanding applications.

Ultrasound weld inspections

detect hidden flaws in welded joints, supporting safety and operational efficiency in Brisbane.

Phased array

testing in Brisbane delivers advanced imaging for detailed assessments of welds and structural components.

Magnetic particle inspection and testing

locates surface and near-surface defects in ferromagnetic materials, ensuring safety. Serving businesses across Brisbane.

Dye penetrant inspection and testing highlights surface cracks in metals and materials, crucial for construction and manufacturing in Brisbane.

Radiography inspection and testing

provides internal imaging of components, identifying defects without compromising material integrity in Brisbane.

Eddy current inspection and testing

in Brisbane evaluates conductive materials for defects, supporting infrastructure and industrial operations.

Visual inspection and testing

identifies defects and irregularities in Brisbane assets, ensuring compliance with safety standards.

Ultrasonic thickness and corrosion testing in Brisbane monitors material degradation, extending asset life and reliability.

Coating inspection

ensures protective coatings meet standards, reducing corrosion in Brisbane's industrial environments.

Hydrostatic pressure testing in Brisbane evaluates the integrity of pipelines and pressure vessels for leaks and weaknesses.

Pressure vessel inspections verify compliance and ensure the safety of high-pressure systems in various Brisbane industries.

API tank inspections

assess the safety and functionality of Brisbane's storage tanks, supporting industrial compliance.

Baroscopic inspection

provides internal visual evaluations of complex systems, minimising downtime and improving safety in Brisbane.

Welding procedure and qualifications

in Brisbane ensures welds comply with industry standards for safety and durability.

Why Brisbane Chooses Us

- Construction Expertise: Tailored solutions to meet the specific needs of Brisbane’s expanding construction and infrastructure sectors.

- Efficient Processes: Minimise downtime with fast, reliable, and professional testing and reporting.

- Regulatory Compliance: Ensure adherence to Brisbane’s safety and operational standards with our NATA-accredited services.

- Advanced Ultrasonic Inspections: Thorough assessments of internal material integrity, reducing risks in high-pressure environments.

- Welding Procedure Support: Certifications and testing to ensure all welding complies with Brisbane’s strict safety standards.

- Comprehensive Services: From non-destructive testing to corrosion monitoring, we cover all inspection needs in Brisbane.

- Local Knowledge: Extensive experience working with Brisbane’s unique industrial and commercial needs.

LJ’s Technical Services combines cutting-edge technology, local expertise, and exceptional service to support Brisbane’s industries with comprehensive testing and inspection solutions.

Contact LJ's Technical Services in Brisbane

Thank you for contacting LJ's Technical Services.

We will get back to you as soon as possible.

Please try again later.

Frequently Asked Questions

-

What areas do you service in Brisbane?

We proudly service the entire Brisbane region and surrounding suburbs, including Brisbane CBD, Logan, Beenleigh, Redcliffe, Ipswich, and Caboolture. If your location isn’t listed, please feel free to contact us to confirm availability. We are dedicated to offering reliable solutions tailored to Brisbane’s industries and requirements.

-

How does magnetic particle inspection ensure safety?

Magnetic particle inspection (MPI) is a non-destructive method used to identify surface and near-surface defects in ferromagnetic materials. By applying a magnetic field and a magnetic particle solution, flaws such as cracks or weld defects become visible. This technique is widely used in Brisbane’s industrial and construction sectors to ensure the safety and integrity of materials and equipment.

-

What is ultrasonic thickness testing, and why is it used?

Ultrasonic thickness testing is a non-destructive technique used to measure material thickness and detect corrosion or thinning in components. By sending sound waves through a material, this method provides accurate measurements without causing damage. This service is vital for industries like manufacturing and construction, where environmental factors such as humidity and wear can lead to material degradation.

Phone

Location

Trading Hours

Business Hours

- Monday

- -

- Tuesday

- -

- Wednesday

- -

- Thursday

- -

- Friday

- -

- Saturday

- Closed

- Sunday

- Closed

Other Locations We Service

Site Link

Location We Service

Our Services

Trading Hours

- Monday

- -

- Tuesday

- -

- Wednesday

- -

- Thursday

- -

- Friday

- -

- Saturday

- Closed

- Sunday

- Closed

ABN: 59 383 740 738

ACN: 149 374 676

Accreditation No. 19154

Date of Accreditation 17 June 2013

ISO/IEC 17025 (2017)