Get In Touch Today 0421 209 254

NDT in South Australia

Advanced testing for South Australia’s agriculture and energy sectors, including ultrasonic and corrosion services.

Contact LJ's Technical Services in South Australia

Thank you for contacting LJ's Technical Services.

We will get back to you as soon as possible.

Please try again later.

Reliable Inspection Solutions

Industries in South Australia depend on reliable testing and inspection services to ensure safety, compliance, and operational success. From manufacturing and energy to transport and agriculture, these sectors face unique challenges that require innovative and precise solutions. LJ’s Technical Services is a trusted provider of advanced inspection and non-destructive testing (NDT) solutions.

We specialise in ultrasonic thickness testing, a crucial method for assessing material integrity and identifying potential weaknesses. Radiography inspections offer advanced internal evaluations, ensuring equipment safety and compliance with strict industry standards. For confined spaces and hard-to-access areas, our baroscopic inspections deliver detailed insights to inform maintenance and repair decisions.

At LJ’s Technical Services, we prioritise accuracy and efficiency to meet the demands of South Australia’s diverse industrial landscape.

Contact us today on

0421 209 254 to learn more about how our testing and inspection solutions can support your South Australian business.

Non-destructive testing in South Australia ensures the safety of assets by identifying flaws without causing material damage.

ISO testing

helps South Australian businesses meet global safety and quality standards, ensuring reliable operations.

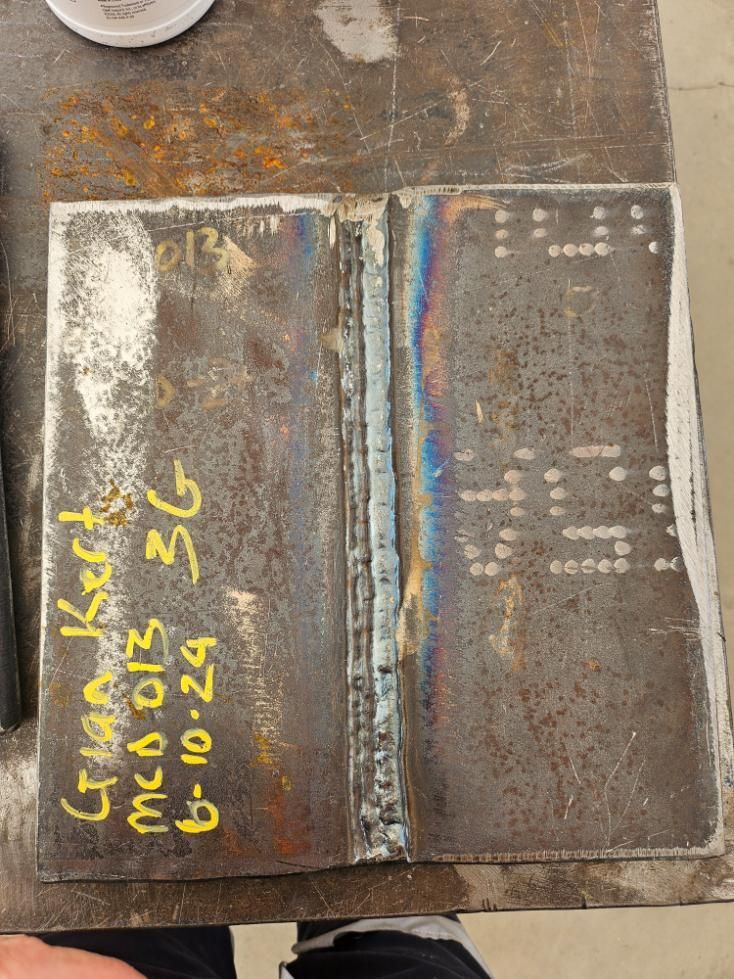

Welding inspection

in South Australia ensures weld quality meets strict industry and safety requirements.

Ultrasound weld inspections

detect internal weld defects, maintaining reliability in critical infrastructure in South Australia.

Phased array in South Australia uses advanced imaging techniques to assess material integrity and weld quality.

Magnetic particle inspection (MPI)

locates surface defects in ferromagnetic materials, ensuring operational safety in South Australia.

Dye penetrant inspection and testing

in South Australia identifies surface cracks in non-porous materials, enhancing integrity.

Radiography inspection and testing

provides internal imaging for components, ensuring safety in high-pressure systems in South Australia.

Eddy current testing in South Australia detects flaws in conductive materials, supporting industrial and manufacturing operations.

Visual inspection and testing

provides quick, effective detection of visible defects in equipment and materials in South Australia.

Ultrasonic thickness testing in South Australia monitors material corrosion, preventing failures in industrial assets.

Coating inspection

ensures protective layers meet standards, safeguarding assets against environmental damage in South Australia.

Hydrostatic pressure testing evaluates the strength and leak resistance of South Australian pipelines and pressure systems.

Pressure vessel inspections in South Australia verify compliance and safety, ensuring high-pressure systems operate reliably.

API tank inspections ensure storage tanks meet South Australian safety standards and perform efficiently.

Baroscopic inspection

uses advanced visual tools to examine internal areas of complex systems in South Australia.

Welding procedure testing

in South Australia ensures welds meet industry standards for safety and durability.

Why Choose LJ’s Technical Services?

- Local Expertise: Understanding South Australia’s diverse industries, from agriculture to manufacturing and energy.

- Comprehensive Services: From ultrasonic testing to corrosion monitoring, we cover all your inspection needs.

- Precision Inspections: Advanced techniques like pressure relief value testing ensure reliable and safe operations.

- Regulatory Compliance: NATA-accredited services ensure adherence to South Australia’s safety and operational standards.

- Proactive Maintenance: Regular testing prevents costly failures and extends the lifespan of critical equipment.

- Efficient Service Delivery: Minimise downtime with prompt, professional testing and reporting.

- Tailored Solutions: Customised services designed to meet South Australia’s specific industry needs and conditions.

LJ’s Technical Services combines advanced technology, local expertise, and a commitment to excellence to support South Australia’s industries with reliable and tailored inspection solutions.

Contact LJ's Technical Services in South Australia

Thank you for contacting LJ's Technical Services.

We will get back to you as soon as possible.

Please try again later.

Frequently Asked Questions

-

What areas do you service in South Australia?

We proudly provide services across South Australia, including Adelaide, Port Augusta, Whyalla, Mount Gambier, Port Lincoln, and Murray Bridge. If your location isn’t listed, please contact us to confirm availability. Our goal is to support businesses across South Australia with high-quality, reliable services that ensure safety and compliance.

-

How does non-destructive testing benefit the construction industry?

Non-destructive testing (NDT) plays a crucial role in ensuring the safety and reliability of construction materials and structures. Techniques like ultrasonic testing, radiography, and magnetic particle inspection are used to identify flaws, cracks, or weaknesses in components without causing damage. These tests are vital for verifying the integrity of critical elements like welds, steel beams, and concrete reinforcements. By detecting issues early, NDT helps prevent structural failures, ensures compliance with safety regulations, and supports long-term durability in construction projects.

-

Why is magnetic particle inspection important?

Magnetic particle inspection (MPI) is a non-destructive technique used to detect surface and near-surface flaws in ferromagnetic materials. It’s particularly effective for identifying cracks, seams, and other defects in components like steel structures, machinery, and welds. MPI is widely used in industries such as automotive, construction, and energy to ensure the safety and reliability of materials. By pinpointing defects early, this method helps prevent failures and supports compliance with stringent safety regulations.

Phone

Location

Trading Hours

Business Hours

- Monday

- -

- Tuesday

- -

- Wednesday

- -

- Thursday

- -

- Friday

- -

- Saturday

- Closed

- Sunday

- Closed

Other Locations We Service

Site Link

Location We Service

Our Services

Trading Hours

- Monday

- -

- Tuesday

- -

- Wednesday

- -

- Thursday

- -

- Friday

- -

- Saturday

- Closed

- Sunday

- Closed

ABN: 59 383 740 738

ACN: 149 374 676

Accreditation No. 19154

Date of Accreditation 17 June 2013

ISO/IEC 17025 (2017)